Page 7 - Russell

P. 7

MADE IN OUR SO

OWN FACILITIES CLOSE

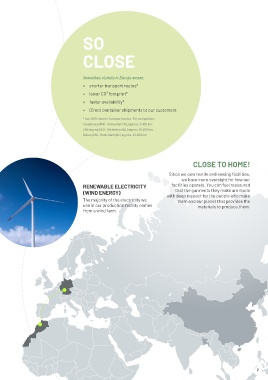

Immediate vicinity to Europe means:

» shorter transport routes*

» lower CO² footprint*

Unlike many other brands, Russell Europe produces the majority of its

T-Shirts in its own production facilities in Morocco. We are proud to have this » faster availability*

opportunity and to have a fantastic and dedicated team in Morocco.

» Direct container shipments to our customers

* over 80% shorter transport routes. For comparison:

Casablanca (MA) - Rotterdam (NL) approx. 3,100 km,

Chittagong (BD) - Rotterdam (NL) approx. 16,500 km,

Dalian (CN) - Rotterdam (NL) approx. 23,200 km

CLOSE TO HOME!

FAIR COMPENSATION Since we own textile and sewing facilities,

We believe every worker has a right to compensation for a we have more oversight for how our

regular work week that is sufficient to meet the worker's RENEWABLE ELECTRICITY facilities operate. You can feel reassured

basic needs and provide some discretionary income. (WIND ENERGY) that the garments they make are made

We believe overtime should not be required The majority of the electricity we with deep respect for the people who make

them and our planet that provides the

to accomplish this. use in our production facility comes materials to produce them.

from a wind farm.

WE REACHED OUR WATER TARGET EARLY

Since 2018, we have achieved a 13.8% reduction in water

intensity, or the amount of water used per pound of fabric

— achieving our goal of a 10% reduction ahead of 2030.

ZERO WASTE

Our sustained commitment to waste reduction

means all our facilities are zero waste. This vital

achievement is made possible through a system of

process optimisation at every location that looks

to better utilise all fabric — from cutting patterns

that minimise scraps to implementing new design

software to reduce samples.

6 6 7 7